Acoustic performance has always been a key strength of ROCKWOOL stone wool, and it remains so. As acoustics become increasingly important for buildings that enrich modern living, ROCKWOOL has chosen to provide living proof of this fundamental aspect of building design. And now it's available to you: the new ROCKWOOL Acoustic Lab, at our headquarters in Hedehusene, Denmark.

At the Acoustic Lab, we carry out precise testing and demonstrations that highlight the sound insulation performance of stone wool. Let your vision of soundproof buildings that perform at their best become a reality. Hear it, feel it, go forward with it!

Spaces that enhance health, comfort and overall wellbeing

In today's fast-moving cities, unwanted noise isn't just an annoyance it's a growing publie health concern. According to the World Health Organization, prolonged exposure to high noise levels can impact sleep, reduce productivity, and even pose long-term health risks. From the rumble of heavy traffic to the noisy upstairs-neighbours in multi-storey buildings, you might have assumed that background noise is just an unavoidable fact of life.

While we can't hit a mute button for most loud sounds, there is a way to tackle the issue. Insulation within buildings can offer a powerful line of defence, with their acoustic properties having the potential to hugely improve the quality of life of anyone using them.

As Daniela Pasquero, our Public Affairs & Innovation Manager at ROCKWOOL Core Solutions puts it, "Sound shapes environments. That's why ROCKWOOL is here to make a difference. Our mission goes beyond reducing noise. It's about creating spaces that enhance health, comfort and overall wellbeing."

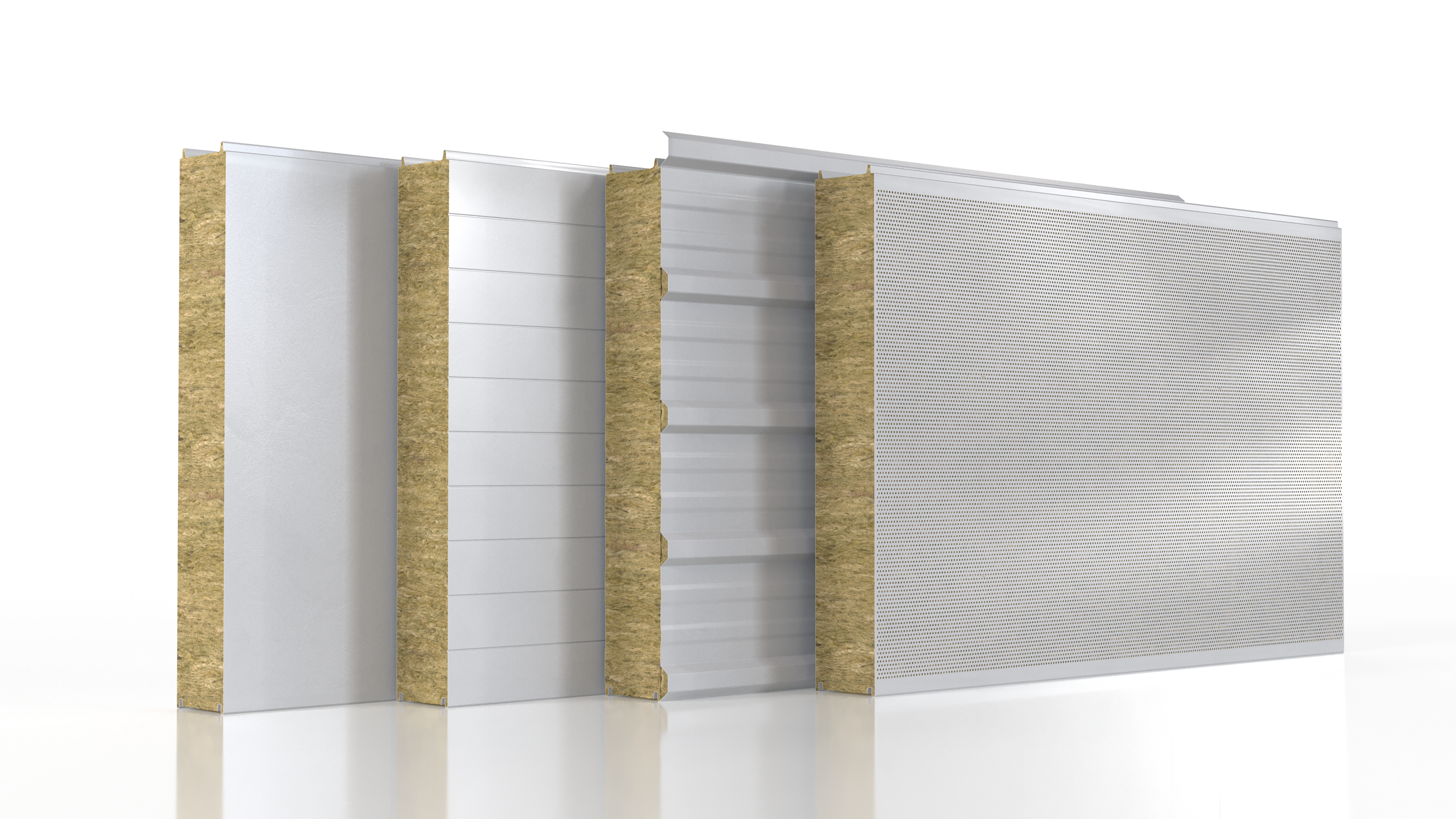

That's why ROCKWOOL is innovating with a bold new investment: a state-of-the art acoustic laboratory. Set to be inaugurated in 2025, this modular facility will allow ROCKWOOL to better serve our customers-and shape the next generation of high-performance building solutions from the inside out.

Acoustic Lab

Hedehusene | Denmark